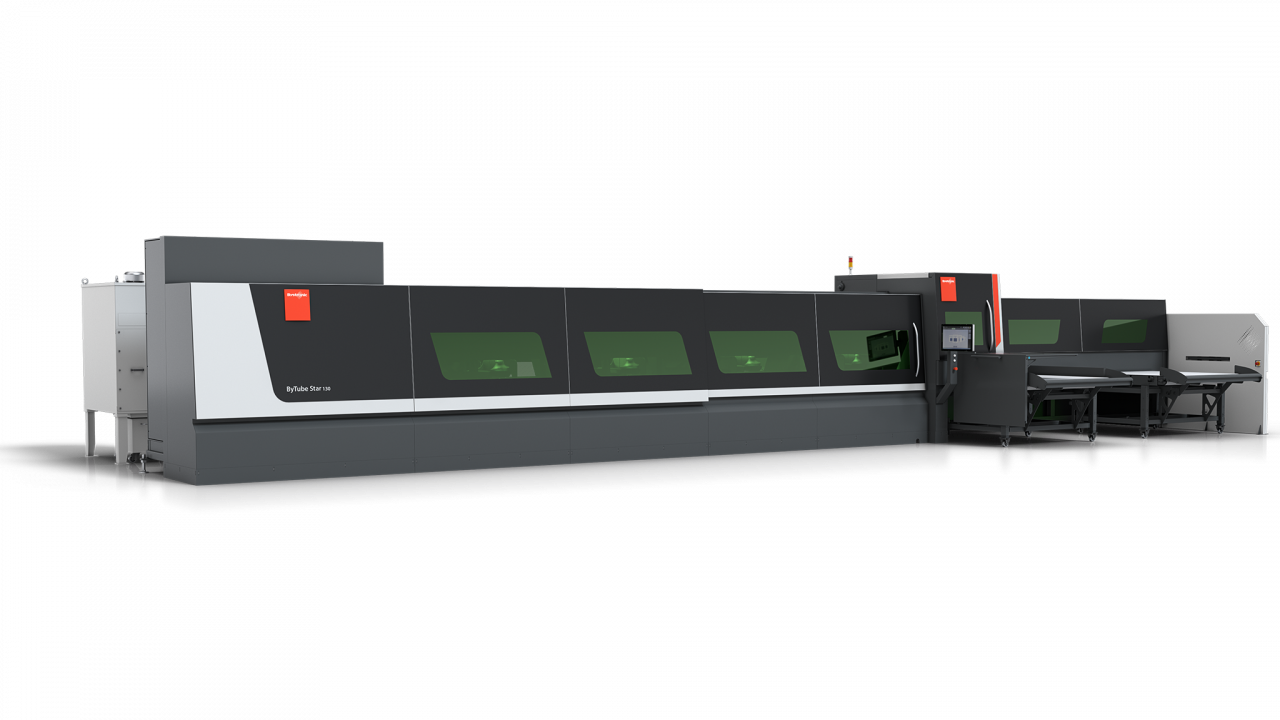

ByTube Star 130Pipe powerful laser cutting performance

Combine the quality and performanceTubing laser cutting - the ultimate solution

In quality assurance at the same time ensure excellent speed, flexibility and efficiency.ByTube Star 130这款高端管材激光器让您的管材激光器业务如虎添翼。使用 ByTube Star 130 进行管材激光切割时,因其卓越的精度、用户友好性以及涵盖开放式型材和椭圆型材的全自动安装,可为您的生产提升质量和性能。

Automatic installationCover open profiles and elliptical profiles

ByTube Star 130 applies to the full bandwidth from 10 to 130 mm, also suitable for the open section.No operator manual intervention.Without stopping to install, so you in laser cutting pipes will have more time for more important matters.Automatic installation means to provide more security for your employees.At the same time, it reduces the risk of human error.

More powerfulFaster speed

New 4 kW strong laser power to ensure that the more rapid cutting.Improved the overall quality of the laser cutting pipes.

The Quick CutTubing laser cutting, high speed and at the same time to ensure high quality

The additional linear cutting head axis to ensure maximum speed under all conditions and quality.In the very small pipe machining can also ensure the quality.

Introduction to help you easily laser cutting pipes.Learn more about our ByTube Star, 130.

ByTube Star 130 technical parametersAll information and data about tubing laser cutting

| ByTube Star 130 | |

| The smallest.The pipe length (with automatic loading) | 2500 mm |

| Is the largest.The pipe length | 6500-8500 mm |

| Is the largest.The pipe weight | 17 kg/m |

| section | U C O L ▯ ◻ |

| Circular cross section size (minimum - the largest). | Ø 10-130 mm |

| Square cross section size (minimum - largest). | 10 x 10-130 x 130 mm |

| The other parts of the closed size (minimum and maximum length) | Ø 10-130 mm |

| Angle of size (L) with equal and unequal leg (minimum - the largest). | 19-120 - mm |

| Channel size, UPN, UPE (minimum - largest). | 19-127 - mm |

| Size flat | 40 x 5 -- 10 mm 130 x |

| The biggest linear velocity X/Y/Z axis | 200/60/60 m/min |

| Maximum rotating speed of spindle | 250 R.P.M. |

| The available length of discharge | 2000-4000-6100 mm |

| The number of controlled axis | 8 |

| Machine weight * | 12, 000 kg |

| The control interface | ByVision Tube |

ByTube Star laserTubing laser cutting power of 4 kW

Using ByTube Star 130 pipe laser cutting alternative time-consuming drilling, sawing, milling or stamping processing.With the increase of laser power and the optimization of the cutting process, you can quickly, automatically and accurately cut enclosed pipe and Angle steel, channel steel, flat steel, and the elliptical profile.

Our pipe laser cutting machine experts are very happy to provide you with advice.

Features and options

-

Productivity and efficiency -

The quality of -

flexibility -

ease -

The sustainable development -

Secure production -

Business success

Fully automatic Settings (including open profile)

Cutting by reducing the setup time to improve productivity, increase the cutting time.

4 kW of fiber laser

Work faster, is not limited to material, the thickness of the material or size.

The Quick Cut - performance model

Maximum cutting performance with the highest productivity.By combining different machine movement, can achieve the highest acceleration value.

Preparation of the nitrogen generator

Does not depend on your gas supplier to ensure consistent gas supply and cutting quality.

In the process of cutting pipe support actively

Controlled axis helps to keep the straight pipe in the process of loading and unloading.Even when dealing with long pipe can ensure accuracy.

4 kW of fiber laser

Through the use of cutting parameter database, according to different materials and thickness can get the best performance and quality.

Laser scanning

Pipe processing, real-time compensation function can ensure even when using low value materials can achieve high cutting precision.

The Quick Cut - quality mode

Small size geometry, no vibration and higher cutting quality, cutting head also need not reset when processing pipes.

Brass and copper + reliability parameters

The complete parameter set can provide more cutting solution.Copper and brass processing package consists of a cutting parameter database and security system.In addition, in view of the possible reflection, but also provide corresponding protection for the operator.

Bundle loader

Without time-consuming adjusting machine, equipment, use very convenient.Using bundle loader, you can quickly easy loading pipe bundle, individual support and open sections.

Cutting a conveyor belt

After the completion of the conveyor belt in cutting collection of artifacts.They provides the operator with sufficient time for logistics transportation, packaging or other tasks.Workpiece directly into the box or tray.

The open section

ByTube Star 130 can not only processing a closed tube, and without modification can processing Angle steel, channel steel and flat steel.

Fully automatic Settings (including open profile)

If you need other products, the operator only into the material, start the program and run the machine.ByTube Star 130不仅操作极其简便,也是特别适合管材加工行业新手的产品。

HMI/ByVision Tube

ByVision Tube of the user interface for can intuitively operation.It to tailor Bystronic machine system, and provide good support for the entire range of application.

Weld find the camera

Automatically find the weld position function is essential for many applications, and especially in the case of bent pipe after cutting.

Laser scanning

In all can ensure high precision cutting conditions, to ensure that the process speed is not affected.This will be the quality control of cutting piece workload fell to the lowest degree.

Fully automatic Settings (including open profile)

This machine equipped with an eye to the future, the automatic setup is suitable for a variety of different pipe or profile, store and/or sorting equipment and help together.

Bundle loader

Using the bundle loader, can be easily manually loaded bundle.Using it can simply connect to the storage device.Ensure continuous loading pipes, so as to minimize downtime, logistics and possible operator errors.

HMI/ByVision Tube

Through the touch screen, easy for operators to provide guidance.ByVision Tube针对 Bystronic 的机器系统量身定制而成,为整个应用范围提供良好支持。

Preparation of the nitrogen generator

Don't depend on your supplier - ensure consistent gas supply and cutting quality.

Fully automatic Settings (including open profile)

Reduce the risk of operator error may cause for the operator to bring more security.

Cutting head

Cutting head adopted "made by Bystronic" fiber laser technology.This means that the maintenance and material procurement to reduce workload.

Laser scanning

In all cutting conditions have always been able to maintain high precision, even in the low value material machining.

The Quick Cut - quality mode

Even in difficult conditions, also always in perfect quality cutting materials with holes, and other features.So that we can reduce wastes and the generation of defective goods.

Fully automatic Settings (including open profile)

Due to realize the automatic tuning machine, need to manually set up machine downtime is greatly reduced.On the one hand, this will lead to improvements in production, on the other hand, it also reduces the cost of individual artifacts.

4 kW of fiber laser

The maximum available power of the small tube laser has a high, to maximize your productivity.When cutting thick material also can guarantee the best quality.

The open section

ByTube Star 130 not only can be used for processing standard pipe, it can also processing Angle steel, channel steel and flat steel.

Preparation of the nitrogen generator

Don't depend on your supplier - ensure consistent gas supply and cutting quality.

Fully automatic Settings (including open profile)

Cutting by reducing the setup time to improve productivity, increase the cutting time.

4 kW of fiber laser

Work faster, is not limited to material, the thickness of the material or size.

The Quick Cut - performance model

Maximum cutting performance with the highest productivity.By combining different machine movement, can achieve the highest acceleration value.

Preparation of the nitrogen generator

Does not depend on your gas supplier to ensure consistent gas supply and cutting quality.

In the process of cutting pipe support actively

Controlled axis helps to keep the straight pipe in the process of loading and unloading.Even when dealing with long pipe can ensure accuracy.

4 kW of fiber laser

Through the use of cutting parameter database, according to different materials and thickness can get the best performance and quality.

Laser scanning

Pipe processing, real-time compensation function can ensure even when using low value materials can achieve high cutting precision.

The Quick Cut - quality mode

Small size geometry, no vibration and higher cutting quality, cutting head also need not reset when processing pipes.

Brass and copper + reliability parameters

The complete parameter set can provide more cutting solution.Copper and brass processing package consists of a cutting parameter database and security system.In addition, in view of the possible reflection, but also provide corresponding protection for the operator.

Bundle loader

Without time-consuming adjusting machine, equipment, use very convenient.Using bundle loader, you can quickly easy loading pipe bundle, individual support and open sections.

Cutting a conveyor belt

After the completion of the conveyor belt in cutting collection of artifacts.They provides the operator with sufficient time for logistics transportation, packaging or other tasks.Workpiece directly into the box or tray.

The open section

ByTube Star 130 can not only processing a closed tube, and without modification can processing Angle steel, channel steel and flat steel.

Fully automatic Settings (including open profile)

If you need other products, the operator only into the material, start the program and run the machine.ByTube Star 130不仅操作极其简便,也是特别适合管材加工行业新手的产品。

HMI/ByVision Tube

ByVision Tube of the user interface for can intuitively operation.It to tailor Bystronic machine system, and provide good support for the entire range of application.

Weld find the camera

Automatically find the weld position function is essential for many applications, and especially in the case of bent pipe after cutting.

Laser scanning

In all can ensure high precision cutting conditions, to ensure that the process speed is not affected.This will be the quality control of cutting piece workload fell to the lowest degree.

Fully automatic Settings (including open profile)

This machine equipped with an eye to the future, the automatic setup is suitable for a variety of different pipe or profile, store and/or sorting equipment and help together.

Bundle loader

Using the bundle loader, can be easily manually loaded bundle.Using it can simply connect to the storage device.Ensure continuous loading pipes, so as to minimize downtime, logistics and possible operator errors.

HMI/ByVision Tube

Through the touch screen, easy for operators to provide guidance.ByVision Tube针对 Bystronic 的机器系统量身定制而成,为整个应用范围提供良好支持。

Preparation of the nitrogen generator

Don't depend on your supplier - ensure consistent gas supply and cutting quality.

Fully automatic Settings (including open profile)

Reduce the risk of operator error may cause for the operator to bring more security.

Cutting head

Cutting head adopted "made by Bystronic" fiber laser technology.This means that the maintenance and material procurement to reduce workload.

Laser scanning

In all cutting conditions have always been able to maintain high precision, even in the low value material machining.

The Quick Cut - quality mode

Even in difficult conditions, also always in perfect quality cutting materials with holes, and other features.So that we can reduce wastes and the generation of defective goods.

Fully automatic Settings (including open profile)

Due to realize the automatic tuning machine, need to manually set up machine downtime is greatly reduced.On the one hand, this will lead to improvements in production, on the other hand, it also reduces the cost of individual artifacts.

4 kW of fiber laser

The maximum available power of the small tube laser has a high, to maximize your productivity.When cutting thick material also can guarantee the best quality.

The open section

ByTube Star 130 not only can be used for processing standard pipe, it can also processing Angle steel, channel steel and flat steel.

Preparation of the nitrogen generator

Don't depend on your supplier - ensure consistent gas supply and cutting quality.

videoComprehensive plan: pipe laser cutting lead to higher quality

Introduction to more quickly and easily pipe laser cutting - with the help of ByTube Star 130, you can on one machine to complete a variety of processing tasks.Automatic installation and user friendly interface has made it more convenient for the tubing laser cutting.The improvement of speed and cutting precision of the optimization to make comprehensive plan more perfect

From the video window

Easy entry

Mature technology and user friendly interface makes it easier for you to fit pipe laser cutting.

Automatic installation

Apply to full bandwidth, from 10 to 130 mm can also be applied to open profiles and elliptical profiles

The Quick Cut features

The additional linear cutting head axis can be in all cutting conditions to ensure the highest speed and quality.

Laser scanning features

Through the real-time compensation pipe bending pipe laser cutting when the cutting accuracy.

Video tutorial

The super serviceCustomized according to your demand, to ensure smooth production

ByCare package

Our well-trained service professionals to ensure efficient production process and the safety of your employees.According to different requirements, we provide services ranging from basic package to comprehensive plans.

Comprehensive customer consultant

We will analyze your production and confirm what are the advantages and disadvantages.This, you can optimize processes and reduce downtime.

Our service

We offer you the super system maintenance and maintenance services.We can according to your request, to provide you with a modified upgrades or attachments, to adjust your machine.If necessary, we'll be able to overhaul.

Our service specialists at any time to provide you with quick and personalized services:

softwareThe ideal supplement: convenient application of tubing laser cutting process

ByVision Tube is simplify the software of tubing laser cutting process.On a touch screen, every function is easy to understand.From the visualization of parts until machining process monitoring - you can quickly and easily for the correct Settings.

BySoft SuiteImprove the efficiency of the process of software

Plate processing is intelligent, networked manufacturing in the future.Bystronic software through your entire digital networking company, to achieve the best way to control your production.