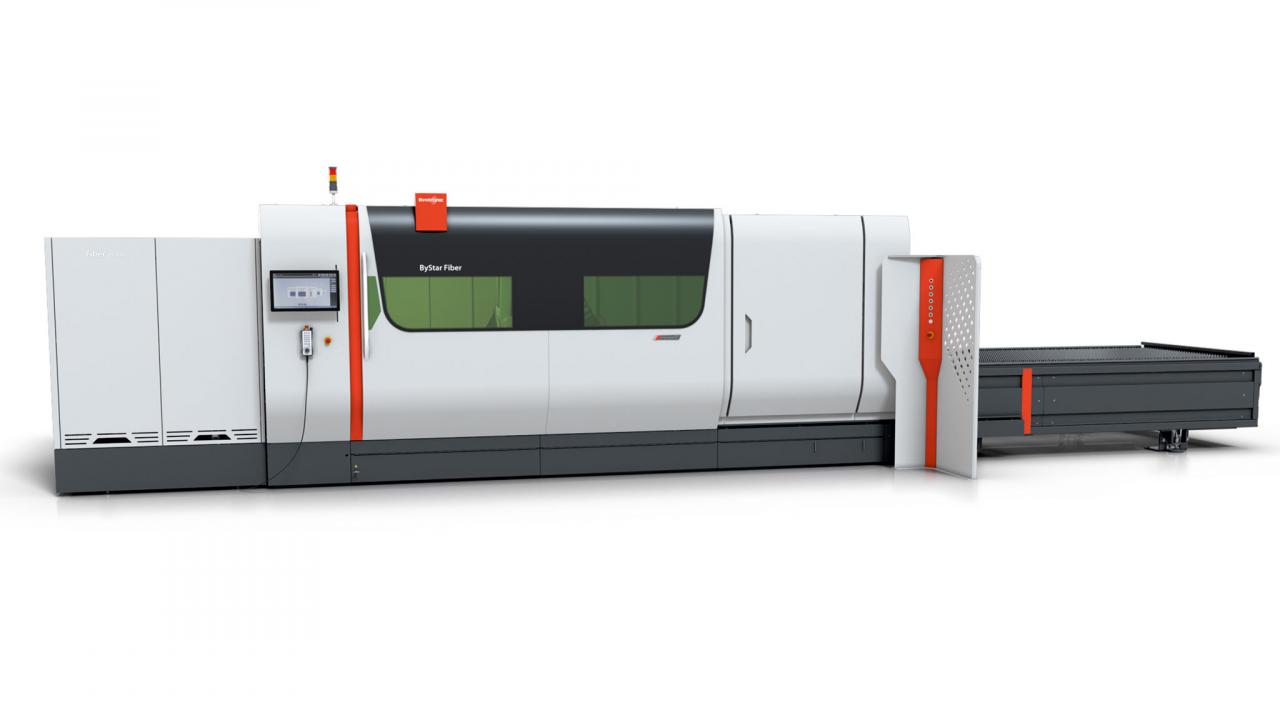

ByStar FiberHigh-speed fiber laser

The highest productivityUltra high speed laser cutting

ByStar Fiber can improve your output and improve the process reliability.With this kind of metal fiber laser, you will be one step ahead in the competition.

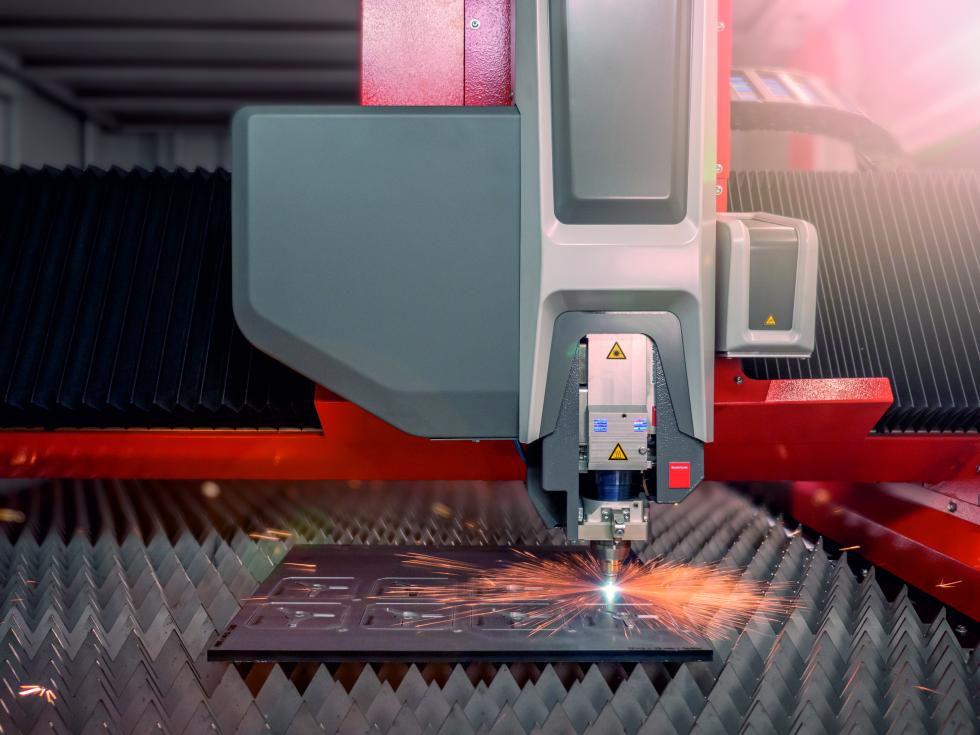

Rapid and high quality20 kW, satisfies the requirement of high application

ByStar Fiber incredible speed advantage.With the top 20 kw power, you will be at a record pace with fiber laser processing orders.

In the process, processing speed will not sacrifice quality - on the contrary: our high quality cutting head is swiss-made, even the most demanding applications also can ensure the highest quality.

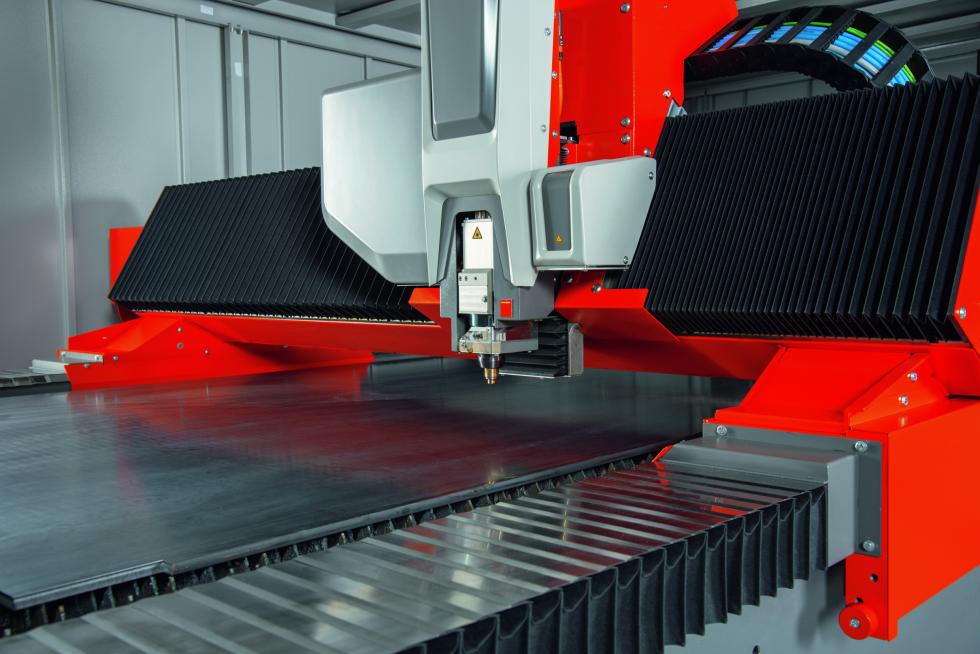

Expand your business scopeProcessing range from steel cover to non-ferrous metal fiber laser

Bulk orders or sporadic small batch processing - ByStar Fiber conform to the requirements of the necessary flexibility, in order to meet the needs of your customer on time.

Our flagship product of fiber laser with you in a variety of products: steel, aluminum and non-ferrous metals, the corresponding models from soup to nuts, and processing of maximum thickness of 50 mm plate.

To achieve their goals fasterThe right automation and software solutions

In the process of plate production, waste much time on the change.With intuitive instructions, you can more quickly convert fiber laser for new orders.In this way, you can make time to focus on the most important matters.You can like smartphone operation, easily through the touch screen operation fiber laser and the connection of the automation system.

Use our Fiber laser ByStar Fiber increase your productivity.

Technical parametersAll the information and data about ByStar Fiber

| ByStar Fiber 3015 | ByStar Fiber 4020 | ByStar Fiber 6225 | ByStar Fiber 8025 | |

| Plank rated size | 3000 x 1500 mm | 4000 x 2000 mm | 6200 x 2500 mm | 8000 x 2500 mm |

| The maximum positioning speed x-y axis linkage | 170 m/min | 170 m/min | 170 m/min | 170 m/min |

| The largest workpiece weight | 1100 kg | 1900 kg | 3650 kg | 4710 kg |

| ByVision betway体育注册西汉姆Cutting operation and manual operation |

|

|

|

|

The laser optical fiber laser systemImprove the quality and output

New ByStar Fiber with 20 kw power.With the increase of laser power and optimization of cutting process, you can at a faster speed and higher precision in fiber laser cutting steel, aluminum, stainless steel, brass and copper, and then improve the quality and output.

Our fiber laser experts are very happy to help you out.

Features and optionsByStar Fiber can match your process

-

Productivity and efficiency -

The quality of -

flexibility -

convenient -

For the future -

Secure production -

Business success

High Laser Power,

With high laser power, can improve the productivity, improving the quality of cutting, and can be processed in the form of economic greater thickness of the plate.For high power cutting, the cutting head of right is an important part of.

Intelligent betway体育注册西汉姆Cutting Process

Improve your productivity: through a full range of process monitoring, the cutting process and stable operation.

betway体育注册西汉姆Cutting Head/Protective Glass

Accuracy and speed - a super cutting head, to the best quality processing thin material and thick materials.In addition, the replacement system with intelligence, which can realize rapid maintenance of protective glass.

MixGas

By mixing nitrogen and oxygen, we will be the merits of different cutting process fusion each other.The use of pure oxygen can obtain excellent cutting quality, and the ideal cutting speed when using pure nitrogen form a perfect match.

The Parameter Wizard

Through Parameter Wizard, you can determine the ideal cutting parameters in just a few minutes, thus reducing piece machining cost.

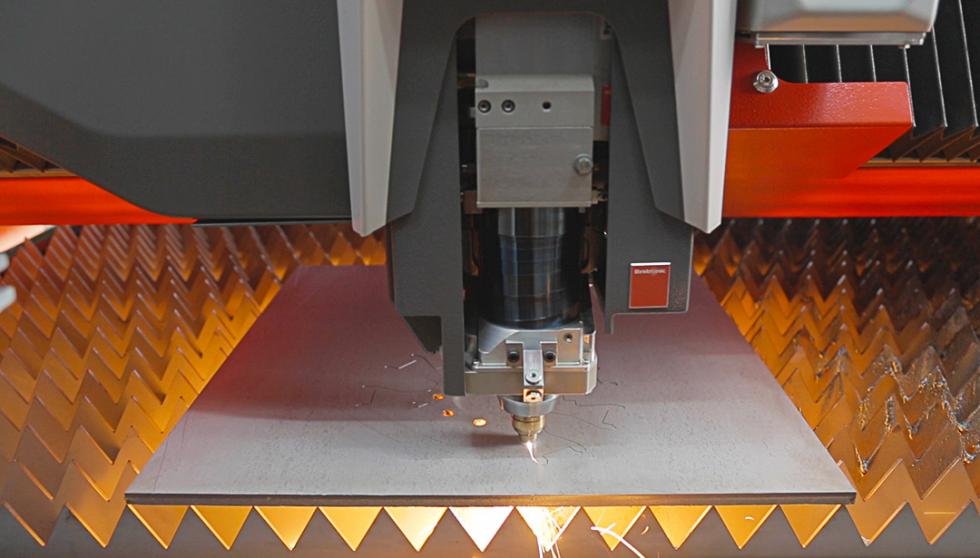

NCT & KerfScan

Through the Nozzle Control Tool (NCT), can achieve rapid and reliable of the Nozzle, and Nozzle distance monitoring.In the process of steel pieces of flame cutting, KerfScan will check the cutting process, identify problems and solve them.It can ensure the stability of the process, without operator intervention.

BeamShaper

In the case of material quality becomes poor, cutting head in manual or automatic BeamShaper will help.Carbon steel, medium and large thickness can improve the cutting quality, and improve process stability.

ByPos Fiber

ByPos Fiber will automatically set the focus position according to the material and thickness.The focus position perfectly matching process.

The Spot Control

According to the plate thickness and materials, the Spot Control will automatically adjust the focus.

Detection Eye

Improve accuracy: with the help of a camera system on cutting planer, Detection Eye will in a few seconds to identify the exact location that is put in the plate and in the process of cutting to provide the operator with help.

Automatic Nozzle Changer

Improve process and shorten the preparation time reliability - fiber laser system on cutting suit cut plan, only 15 seconds can replace the nozzle.To reduce costs while increasing productivity.

HMI/Cubetway体育注册西汉姆tting Plan Editor

Copy, delete, rotate, move and add - with the editor, you can easily adjust the existing cutting suit cut plan

The Machine Size

No matter what material, and the application of how, can ensure that the correct size - we have a variety of specifications for you to choose and buy machines.

HMI/Cubetway体育注册西汉姆tting Plan Editor

As convenient as using smartphones.Intuitive HMI interface to simplify the machine operation, which in turn increase productivity

Automatic Nozzle Changer

Improve process and shorten the preparation time reliability - fiber laser system on cutting suit cut plan, only 15 seconds can replace the nozzle.To reduce costs while increasing productivity.

Detection Eye

Improve accuracy: with the help of a camera system on cutting planer, Detection Eye will in a few seconds to identify the exact location that is put in the plate and in the process of cutting to provide the operator with help.

The Parameter Wizard

Through Parameter Wizard, you can determine the ideal cutting parameters in just a few minutes, thus reducing piece machining cost.

HMI/Cubetway体育注册西汉姆tting Plan Editor

With editor, can easily adjust the existing cutting suit cut plan.

Preparation for N2 - the Generator

Not the restriction of the gas suppliers - ensures that the cutting quality of the constant and stable gas supply.

Rotary Axis

Quickly and easily switch between sheet and tube laser processing.

Tilt Prevention

Software functions to prevent collision with tilt artifacts, and supports automatic sorting process.The optimized cutting suit cut plan, avoid cutting the workpiece after tilt.

The Cut Control Fiber

With the Cut Control integration in the Fiber sensor, which can be interrupted cutting process in cutting problems.Use other functions, can be highly responsible way to handle with cutting materials and machines.These capabilities include nitrogen during cutting process monitoring, cut into the process of monitoring or plate recognition at the edge of the correct position.

Intelligent betway体育注册西汉姆Cutting Process

Improve your productivity: through a full range of process monitoring, the cutting process and stable operation.

NCT & KerfScan

Through the Nozzle Control Tool (NCT), can achieve rapid and reliable of the Nozzle, and Nozzle distance monitoring.In the process of steel pieces of flame cutting, KerfScan will check the cutting process, identify problems and solve them.It can ensure the stability of the process, without operator intervention.

MixGas

By mixing nitrogen and oxygen, we will be the merits of different cutting process fusion each other.For example, when cutting thickness larger steel, you can improve the cutting quality.

HP Shop Air

Through this function, you can reduce the unit cost, and can be used compressed air to cut 3 mm to 40 mm thickness of the plate

Preparation for N2 - the Generator

Not the restriction of the gas suppliers - ensures that the cutting quality of the constant and stable gas supply.

Rotary Axis

Convenient processing complex and simple geometric shapes, such as sheet and pipe.

High Laser Power,

With high laser power, can improve the productivity, improving the quality of cutting, and can be processed in the form of economic greater thickness of the plate.For high power cutting, the cutting head of right is an important part of.

Intelligent betway体育注册西汉姆Cutting Process

Improve your productivity: through a full range of process monitoring, the cutting process and stable operation.

betway体育注册西汉姆Cutting Head/Protective Glass

Accuracy and speed - a super cutting head, to the best quality processing thin material and thick materials.In addition, the replacement system with intelligence, which can realize rapid maintenance of protective glass.

MixGas

By mixing nitrogen and oxygen, we will be the merits of different cutting process fusion each other.The use of pure oxygen can obtain excellent cutting quality, and the ideal cutting speed when using pure nitrogen form a perfect match.

The Parameter Wizard

Through Parameter Wizard, you can determine the ideal cutting parameters in just a few minutes, thus reducing piece machining cost.

NCT & KerfScan

Through the Nozzle Control Tool (NCT), can achieve rapid and reliable of the Nozzle, and Nozzle distance monitoring.In the process of steel pieces of flame cutting, KerfScan will check the cutting process, identify problems and solve them.It can ensure the stability of the process, without operator intervention.

BeamShaper

In the case of material quality becomes poor, cutting head in manual or automatic BeamShaper will help.Carbon steel, medium and large thickness can improve the cutting quality, and improve process stability.

ByPos Fiber

ByPos Fiber will automatically set the focus position according to the material and thickness.The focus position perfectly matching process.

The Spot Control

According to the plate thickness and materials, the Spot Control will automatically adjust the focus.

Detection Eye

Improve accuracy: with the help of a camera system on cutting planer, Detection Eye will in a few seconds to identify the exact location that is put in the plate and in the process of cutting to provide the operator with help.

Automatic Nozzle Changer

Improve process and shorten the preparation time reliability - fiber laser system on cutting suit cut plan, only 15 seconds can replace the nozzle.To reduce costs while increasing productivity.

HMI/Cubetway体育注册西汉姆tting Plan Editor

Copy, delete, rotate, move and add - with the editor, you can easily adjust the existing cutting suit cut plan

The Machine Size

No matter what material, and the application of how, can ensure that the correct size - we have a variety of specifications for you to choose and buy machines.

HMI/Cubetway体育注册西汉姆tting Plan Editor

As convenient as using smartphones.Intuitive HMI interface to simplify the machine operation, which in turn increase productivity

Automatic Nozzle Changer

Improve process and shorten the preparation time reliability - fiber laser system on cutting suit cut plan, only 15 seconds can replace the nozzle.To reduce costs while increasing productivity.

Detection Eye

Improve accuracy: with the help of a camera system on cutting planer, Detection Eye will in a few seconds to identify the exact location that is put in the plate and in the process of cutting to provide the operator with help.

The Parameter Wizard

Through Parameter Wizard, you can determine the ideal cutting parameters in just a few minutes, thus reducing piece machining cost.

HMI/Cubetway体育注册西汉姆tting Plan Editor

With editor, can easily adjust the existing cutting suit cut plan.

Preparation for N2 - the Generator

Not the restriction of the gas suppliers - ensures that the cutting quality of the constant and stable gas supply.

Rotary Axis

Quickly and easily switch between sheet and tube laser processing.

Tilt Prevention

Software functions to prevent collision with tilt artifacts, and supports automatic sorting process.The optimized cutting suit cut plan, avoid cutting the workpiece after tilt.

The Cut Control Fiber

With the Cut Control integration in the Fiber sensor, which can be interrupted cutting process in cutting problems.Use other functions, can be highly responsible way to handle with cutting materials and machines.These capabilities include nitrogen during cutting process monitoring, cut into the process of monitoring or plate recognition at the edge of the correct position.

Intelligent betway体育注册西汉姆Cutting Process

Improve your productivity: through a full range of process monitoring, the cutting process and stable operation.

NCT & KerfScan

Through the Nozzle Control Tool (NCT), can achieve rapid and reliable of the Nozzle, and Nozzle distance monitoring.In the process of steel pieces of flame cutting, KerfScan will check the cutting process, identify problems and solve them.It can ensure the stability of the process, without operator intervention.

MixGas

By mixing nitrogen and oxygen, we will be the merits of different cutting process fusion each other.For example, when cutting thickness larger steel, you can improve the cutting quality.

HP Shop Air

Through this function, you can reduce the unit cost, and can be used compressed air to cut 3 mm to 40 mm thickness of the plate

Preparation for N2 - the Generator

Not the restriction of the gas suppliers - ensures that the cutting quality of the constant and stable gas supply.

Rotary Axis

Convenient processing complex and simple geometric shapes, such as sheet and pipe.

videoFiber laser ByStar Fiber: for a few minutes can obtain perfect results

A ByStar Fiber, you not only can simplify the process.With convenient operation and fast configuration, can not only improve productivity, also can ensure the reliability of excellence.

Video highlights

Widely used

Both carbon steel, stainless steel, aluminum and non-ferrous metals - production application is very extensive.Can use this kind of fiber laser processing maximum 50 mm thickness plate.

High process reliability

Bystronic automation solution to ensure optimal load and maximum reliability of unattended operation.

Simplicity of operation

With the aid of a 21.5 -inch touch screen, betway体育注册西汉姆you can like smartphone operation easily operating software ByVision Cutting.

Rapid configuration

For any orders, « Parameter Wizard » options can perfect parameters in a few minutes.

A short video tutorial

Born to automationByStar Fiber optical Fiber laser

For your process automation.With our efficient solution, not only can you speed up the material flow, in the process of loading can also give full play to the mature laser performance.

The ideal of our automation solution is ByStar Fiber supplement.During the unattended, they can ensure ideal utilization and optimum process reliability.

The super serviceCustomized according to your demand, to ensure smooth production

ByCare package

Our well-trained service professionals to ensure efficient production process and the safety of your employees.According to different requirements, we provide services ranging from basic package to comprehensive plans.

Comprehensive customer consultant

We will analyze your production and confirm what are the advantages and disadvantages.This, you can optimize processes and reduce downtime.

Our service

We offer you the super system maintenance and maintenance services.We can according to your request, to provide you with a modified upgrades or attachments, to adjust your machine.If necessary, we'll be able to overhaul.

Our service specialists at any time to provide you with fast and personalized service

softwareImprove the comfortbetway体育注册西汉姆: with ByVision Cutting fiber laser processing has become very simple

Through intelligebetway体育注册西汉姆nt software ByVision Cutting save tedious work.In the daily work of tension, independent function provides the support for you, from day 1 start to ensure that the ideal results.

« Parameter Wizard » option in minutes you can determine the ideal configuration for you.

BySoft SuiteImprove the efficiency of the process of software

Plate processing is intelligent, networked manufacturing in the future.Bystronic software through your entire digital networking company, to achieve the best way to control your production.