Double factoryUnder the same roof of the two factories

Stoppani Metal Systems,

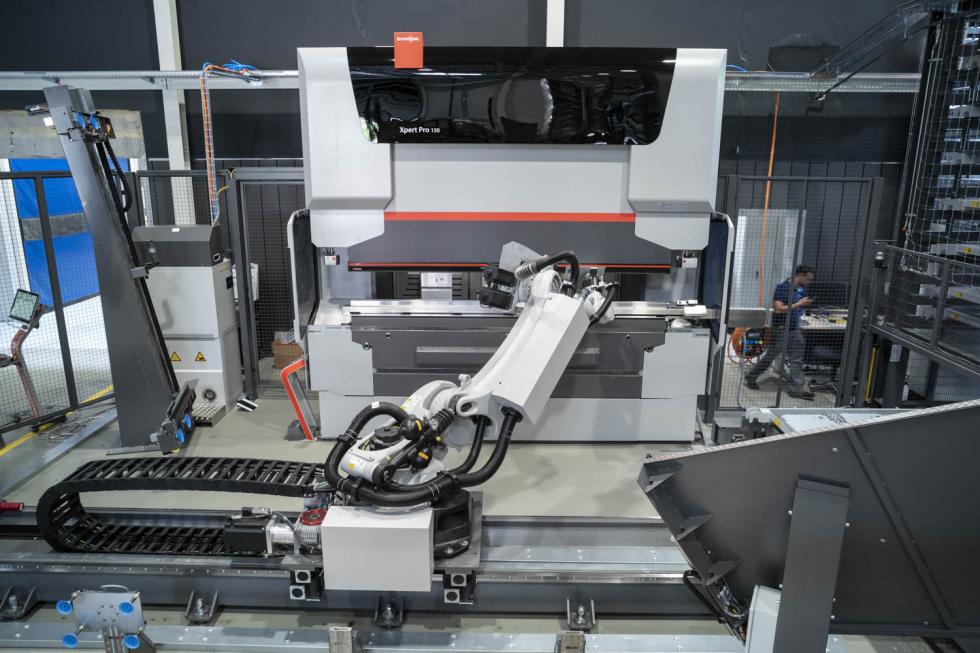

Swiss foundry enterprises SwissFactory Group introduced the new structure, especially improve the subsidiary Stoppani Metal Systems in the level of modernization in the field of sheet Metal processing.Now is implementing the "double factory" project, in the factory, people go to work during the day, the machine work in the evening.This should be fully automatic digital factory to independent production - to ensure Stoppani international competitiveness.As the only supplier, Bystronic can satisfy these requirements.

"We are under the same roof built two plants - a human factory, a digital factory."

Hans Gattlen, Stoppani partners and management committee chairman

Bystronic solution

From vision to Smart Factory: in order to be able to headquarters in Switzerland competitive for production, fully automated production process is required.In order to improve efficiency and productivity, and ensure profitability.