15 kw new dimension15 kw new dimension speed, accuracy and flexibility

Speed, precision, flexibility: use the new 15 kw laser power new ByStar Fiber accurately cut 1-30 mm thick steel, aluminum alloy and stainless steel, as well as the thickness under 20 mm brass and copper.The laser power to a maximum of 50% increased, plate processors this further optimize its production process.

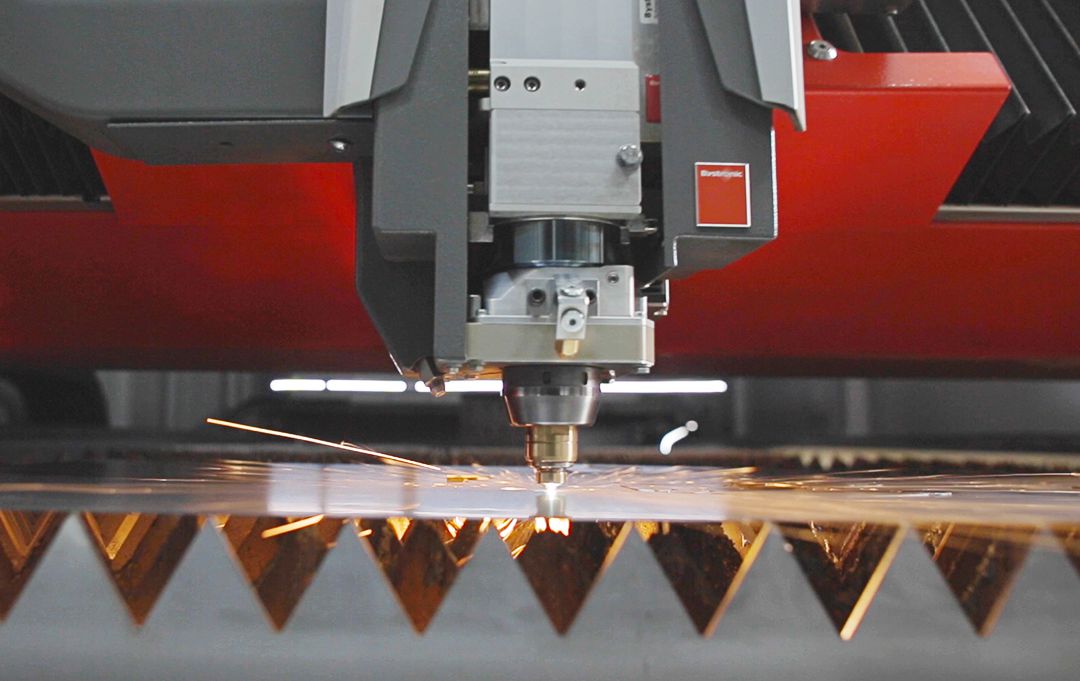

In order to better in the increasingly fierce competition environment help plate processors, now bystronic opens a new optical Fiber laser cutting dimensions: 15 kw laser power ByStar Fiber.The high-end bystronic glass fiber laser represents a highly sophisticated technology, stable and high power laser cutting process, but also represents a wide range of applications.Compared with the previous 10 kw laser, ByStar Fiber using 15 kw laser average cutting speed can be increased by 50% (for laser cutting using nitrogen).Thus, plate processors can from higher productivity and lower the unit cost of benefit, because use 15 kw new ByStar Fiber can be accurately and reliably cut 1 to 30 mm thick steel, aluminum alloy and stainless steel, and the thickness under 20 mm brass and copper.15 kw laser power can also be used for up to 50 mm thick steel and aluminum alloy in other USES, thus model flexibility for the mass production and temporary customer orders.Aluminum alloy, non-ferrous metals and steel, efficient bystronic cutting head can with maximum precision cutting thick plate and profiles.In 3015 and 4020 ByStar ByStar all can obtain the new power level.

With the help of "BeamShaper" to achieve high quality cut

With the unique "BeamShaper" optional, "BeamShaper" function for the 30 mm thick plate quality of neat cutting section and high operating reliability.New purchase 15 kw ByStar Fiber can choose the function, also can add later."BeamShaper" according to a larger plate thickness and wave plate quality adjusting the shape of a laser beam.For 20 to 30 mm plate thickness, the function can improve the quality of the cutting section, and the cutting speed compared with the common 10 kw machine up to 50%.A new efficient bystronic flabetway体育注册西汉姆gship product can also use the software "ByVision Cutting" on a 21.5 -inch touch screen control.Operating as convenient as using smartphones.

Bystronic automation equipment to optimize the material flow

A wide range of automation and intelligent function even in the case of unmanned production can guarantee the best utilization rate of equipment and process reliability.For by the best material flow in the process of laser cutting for higher processing speed, super for ByStar Fiber offers a wide range of automation solutions.Scheme including loading system, sorting solution and can be personalized configuration of the loading system.According to the existing processing environment and space, you can create a seamless integration of automatic laser cutting process.

ByTrans Cross is the first of the super provide suitable loading solution.The automation equipment can be flexible to adapt to the changing in the process of laser cutting orders and production rhythm.Can realize different application scenarios.As Bridges, automation ByTrans Cross can be integrated in the laser cutting equipment and material library, in order to guide the material flow.ByTrans Cross can also be used in the case of not connected material library used as a stand-alone solution, provides a variety of blank thickness plate for laser cutting equipment, and other raw materials.ByTrans Cross base version with two stage cart, can be used in stand-alone applications as base material.ByTrans Cross with sorting solution BySort, best can according to customer demand as additional solutions for integration, so as to use in the field of cleaning more diverse.User finish machining of the workpiece can be moved to warehouse after sorting, or after sorting in laser cutting equipment near the auxiliary cutting position.For example, if all must, in accordance with the order of cutting piece in mass processing separate sorting, the device is very useful.BySort a big advantage is that can keep all artifacts accurately placed in one location: especially suitable for large cutting task of artificial difficult to move.Accurate positioning on the tray of the workpiece can be easily in the manual and automatic process after the automated processing, because their position has been accurately defined.