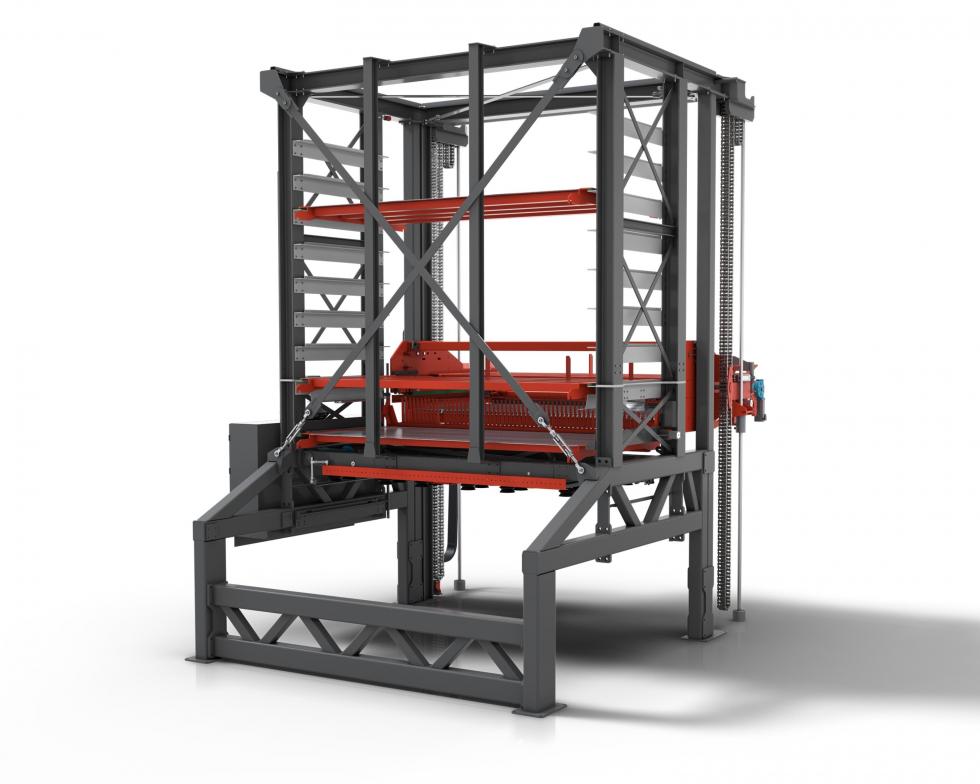

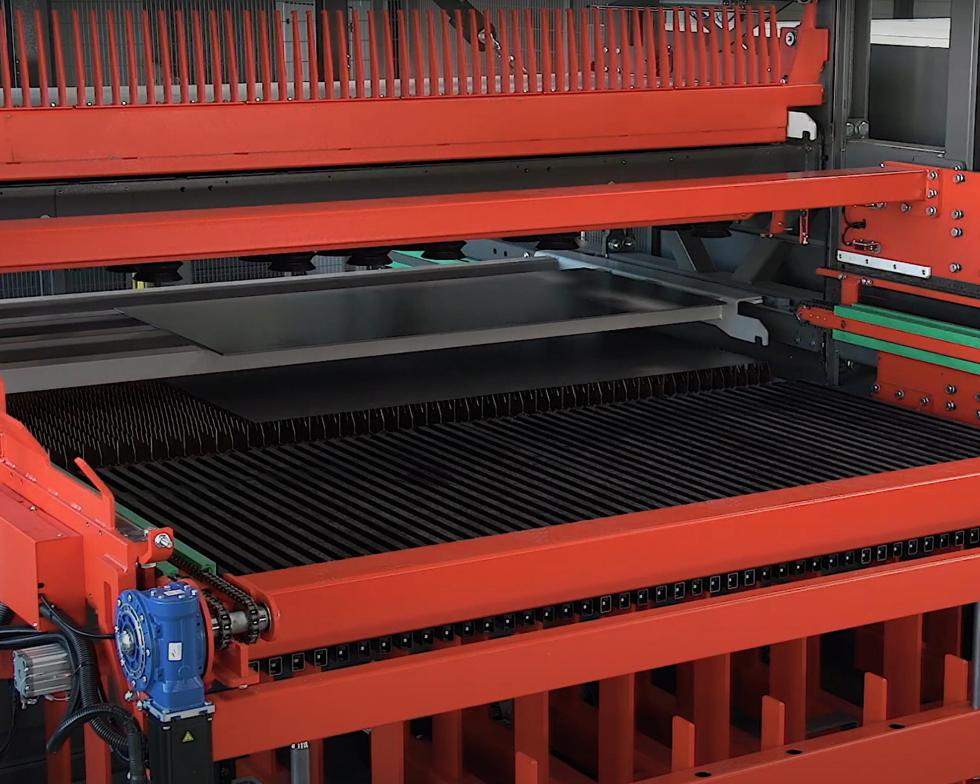

ByTower CompactAutomatic feeding and discharge, with integrated warehouse, form a complete set for laser cutting systems

Loading and dischargeEquipped with a store towers laser automation system

Thanks to ByTower Compact intelligent design (up-down material system with warehouse), further enhance the productivity of the super laser, at the same time without having to take up a lot of space.The device is designed for occupy as small as possible in the area.Pallet change fully automatic, so whatever the scale of the enterprise, can realize the unattended or unattended.

Compact and automaticAutomation equipment to improve productivity

Automation solutions to optimize the material flow and improve machine utilization ratio and improve operation in the production process and process reliability.

For your laser cutting equipment, with the compact bystronic system, can realize automatic feeding and tray.

The ideal space utilizationSave a space system, realizing unattended production

The device is designed for occupy as small as possible in the area.In order to make full use of effective space, can customize the loading height of tower according to your individual needs.Thus, ByTower Compact as integration solutions, which can realize the production of unattended or unattended.

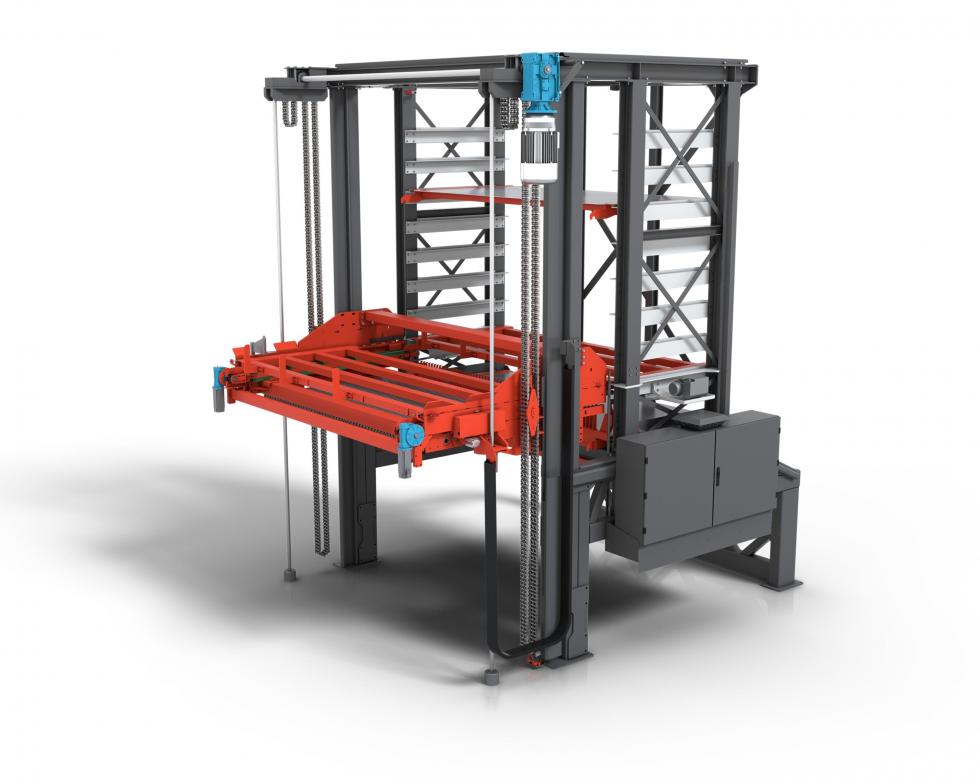

Rapid supply of materialShorten the non-production time and improve productivity

Laser automatic switching of table feeding and discharge automatically.Thus to optimize the utilization of the whole system, cancel or significantly shorten the non-production time.This will further enhance the productivity.

Loading and dischargeEquipped with a store towers laser automation system

Thanks to ByTower Compact intelligent design (up-down material system with warehouse), further enhance the productivity of the super laser, at the same time without having to take up a lot of space.The device is designed for occupy as small as possible in the area.Pallet change fully automatic, so whatever the scale of the enterprise, can realize the unattended or unattended.

Compact and automaticAutomation equipment to improve productivity

Automation solutions to optimize the material flow and improve machine utilization ratio and improve operation in the production process and process reliability.

For your laser cutting equipment, with the compact bystronic system, can realize automatic feeding and tray.

The ideal space utilizationSave a space system, realizing unattended production

The device is designed for occupy as small as possible in the area.In order to make full use of effective space, can customize the loading height of tower according to your individual needs.Thus, ByTower Compact as integration solutions, which can realize the production of unattended or unattended.

Rapid supply of materialShorten the non-production time and improve productivity

Laser automatic switching of table feeding and discharge automatically.Thus to optimize the utilization of the whole system, cancel or significantly shorten the non-production time.This will further enhance the productivity.

Bystronic ByTower of Compact to help you improve productivity.We are very glad to answer you all kinds of questions.

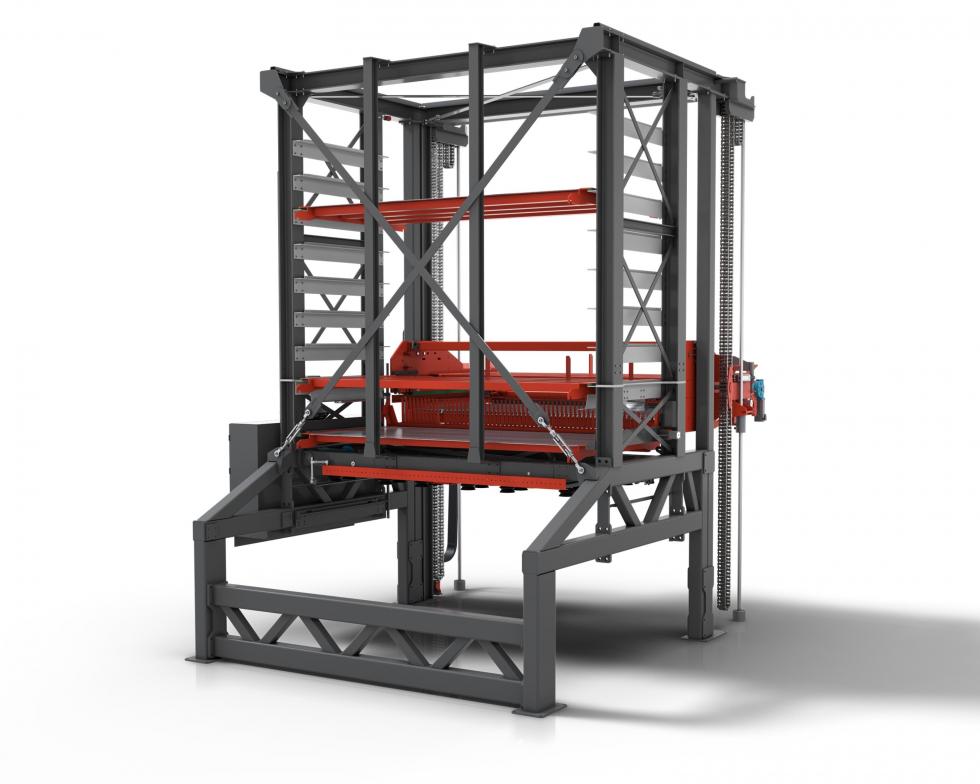

Technical parametersAll of the information ByTower Compact

| ByTower Compact 3015 + ByTower Compact 3015 P | |

| Plank nominal size | 3000 x 1500 mm |

| The largest board size | 3025 x 1520 mm |

| Single plate thickness | 25 mm |

| Maximum plate weight | 900 kg |

| No + N optional equipment when a up-down material through rough time | 180 s |

| With Fast Cycle + N optional equipment of a loading Cycle roughly time | 70 s |

videoThe ByTower space-saving system: work Compact

Equipment as little as possible to take up floor space.With the tray of automatic feeding and cutting, the production of realizing unattended

From the video window

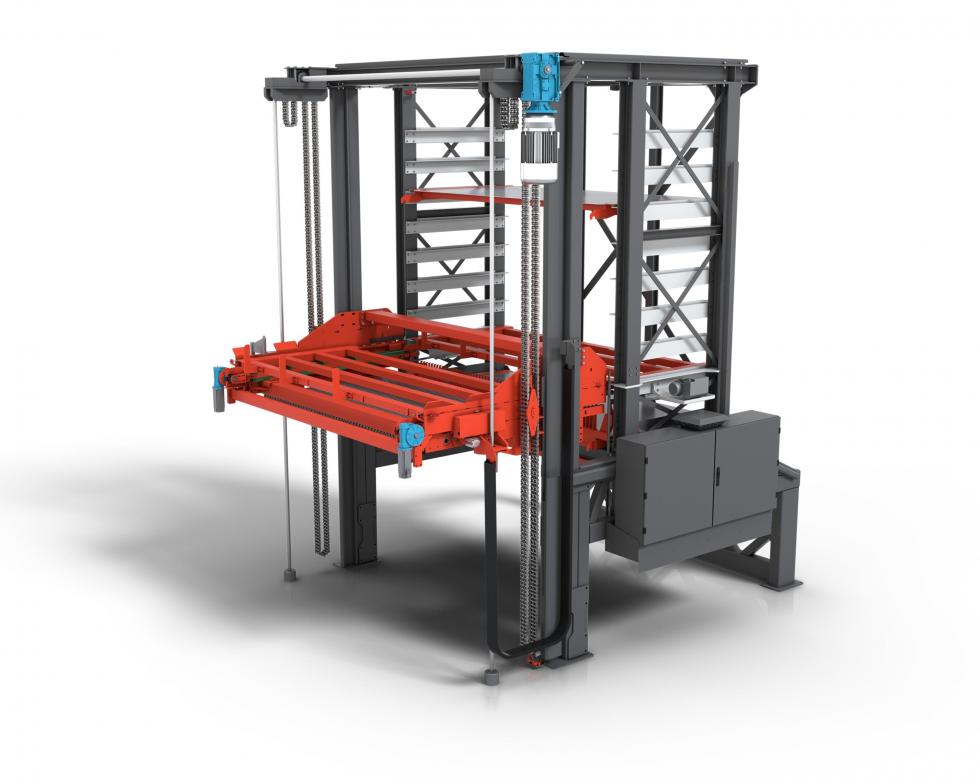

Improve the production efficiency

For your laser cutting system, ByTower Compact can realize the automation of feeding and discharge process.As a result, cutting processing speed of workpiece can be significantly enhanced.

Automation of production

With automatic system, realizes the unmanned production.In this way, your staff can focus on important tasks.

Height adjustable

Tower height can be cut according to specific needs.In this way, can optimize the use of available space efficiency.

The dual advantage

You can choose between two different configuration, to manage the plank group with or without wooden pallets.

If you are looking for laser feeding and discharge of the automation system have any questions, we are very happy to provide you with advice.

The super serviceCustomized according to your demand, to ensure smooth production

ByCare package

Our well-trained service professionals to ensure efficient production process and the safety of your employees.According to different requirements, we provide services ranging from basic package to comprehensive plans.

Comprehensive customer consultant

We will analyze your production and confirm what are the advantages and disadvantages.This, you can optimize processes and reduce downtime.

Our service

We offer you the super system maintenance and maintenance services.We can according to your request, to provide you with a modified upgrades or attachments, to adjust your machine.If necessary, we'll be able to overhaul.

Our service specialists at any time to provide you with quick and personalized services: