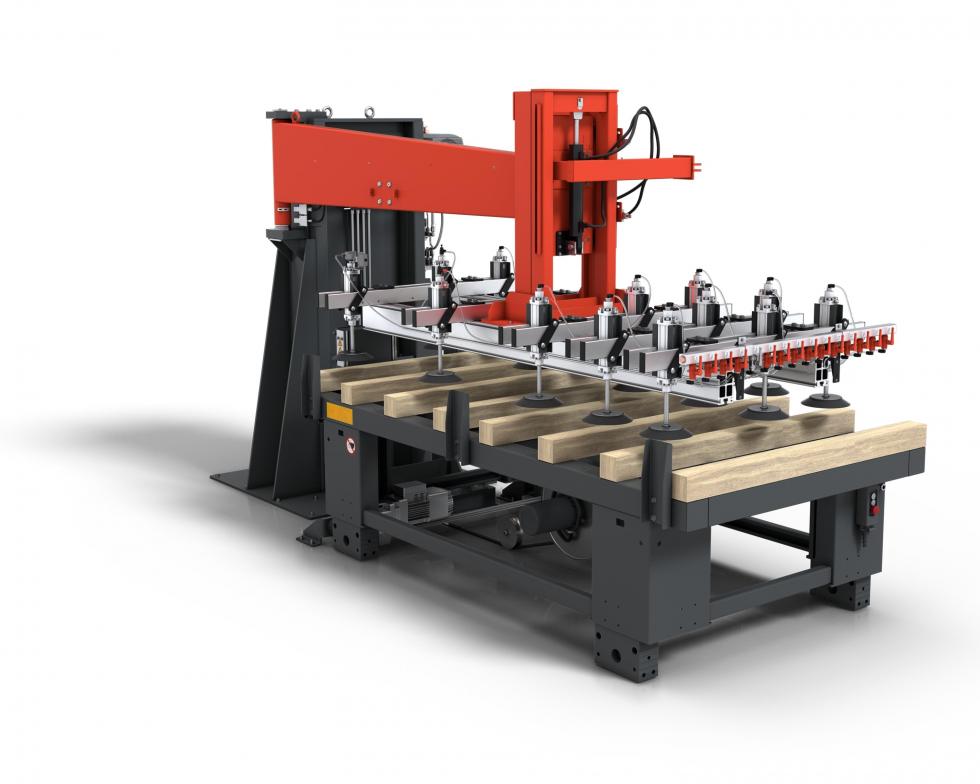

ByloaderSheet automatic feeding system, to achieve efficient handling

Rapid feed systemTo make your life easier

With Byloader, you can further simplify the process of laser cutting.It can achieve rapid loading of raw materials on the automatic switching work bench, thus optimizing the loading process, automatic, fast and reliable.

Reduce the consumption ofTo save time and cost

Feeding system for each of the suction cups can be independent of all other suction cups alone.This can reduce the energy consumption of automation system in the process of loading.In addition, can also be the management of the small format specification.

Mesh sizes andintuitive

With integrated control system, you can easily and intuitively Byloader operation.By the super laser cutting equipment operation terminal for the corresponding operation.In this way, just a touch screen can complete all operations.

Improved accessFor work manual unloading

We dojo.provide you a sheet metal table with an electric drive home a fixed table. This facilitates the loading process and the the org.eclipse.swt.accessibility of the shuttle tbetway体育注册西汉姆able of your laser cutting system for manual unloading.

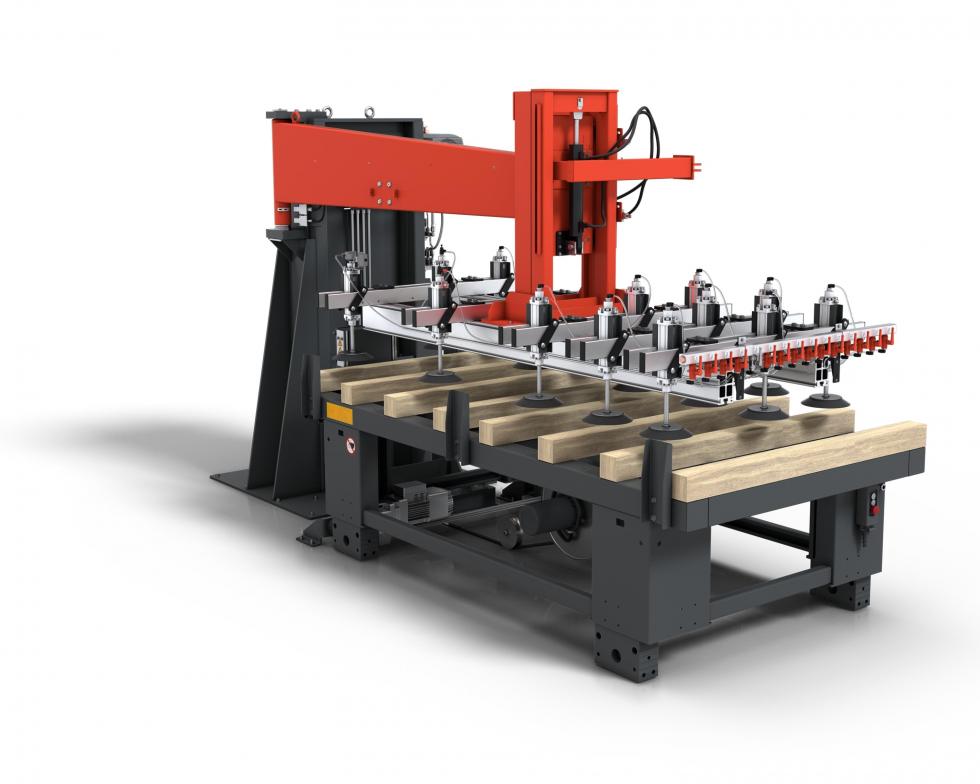

Rapid feed systemTo make your life easier

With Byloader, you can further simplify the process of laser cutting.It can achieve rapid loading of raw materials on the automatic switching work bench, thus optimizing the loading process, automatic, fast and reliable.

Reduce the consumption ofTo save time and cost

Feeding system for each of the suction cups can be independent of all other suction cups alone.This can reduce the energy consumption of automation system in the process of loading.In addition, can also be the management of the small format specification.

Mesh sizes andintuitive

With integrated control system, you can easily and intuitively Byloader operation.By the super laser cutting equipment operation terminal for the corresponding operation.In this way, just a touch screen can complete all operations.

Improved accessFor work manual unloading

We dojo.provide you a sheet metal table with an electric drive home a fixed table. This facilitates the loading process and the the org.eclipse.swt.accessibility of the shuttle tbetway体育注册西汉姆able of your laser cutting system for manual unloading.

Using our automatic feeding system, in order to simplify the process.We are very glad to answer you all kinds of questions.

Technical parametersByloader all of the information

| Byloader 3015 | Byloader 4020 | |

| Plank rated size | 3000 x 1500 mm | 4000 x 2000 mm |

| On the thickness of the material stack | 0.8-25 mm | 0.8-25 mm |

| Maximum plate weight | 890 kg | 1580 kg |

Bright spot

If you have any questions about Byloader feed system, we are very happy to provide advice.

The super serviceCustomized according to your demand, to ensure smooth production

ByCare package

Our well-trained service professionals to ensure efficient production process and the safety of your employees.According to different requirements, we provide services ranging from basic package to comprehensive plans.

Comprehensive customer consultant

We will analyze your production and confirm what are the advantages and disadvantages.This, you can optimize processes and reduce downtime.

Our service

We offer you the super system maintenance and maintenance services.We can according to your request, to provide you with a modified upgrades or attachments, to adjust your machine.If necessary, we'll be able to overhaul.

Our service specialists at any time to provide you with quick and personalized services: