Modular Tool ChangerFor bending machine to realize the automatic tool change

Shorten the installation timeWith automatic tool change for bending processing speed

Don't waste your time: up to 70% of the time can take up load bending process.This is not only time-consuming, and cutting tools for large size is particularly exhausting.

Modular Tool Changer for your staff and burden and increase productivity.It can on your bending machine which Pro automatic changing tool, and ensure the high precision of bending process.

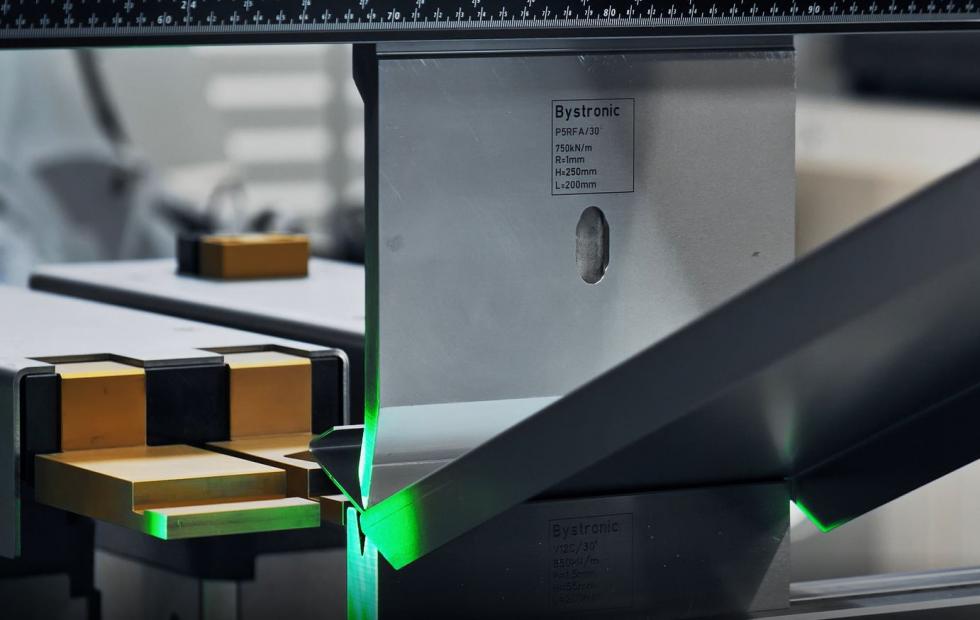

To protect your parts and toolsExtend the service life of cutting tools

Bending machine of automatic cleaning function to ensure the accurate positioning tool, and further improve the accuracy of bending process.Protective action to prolong tool life.

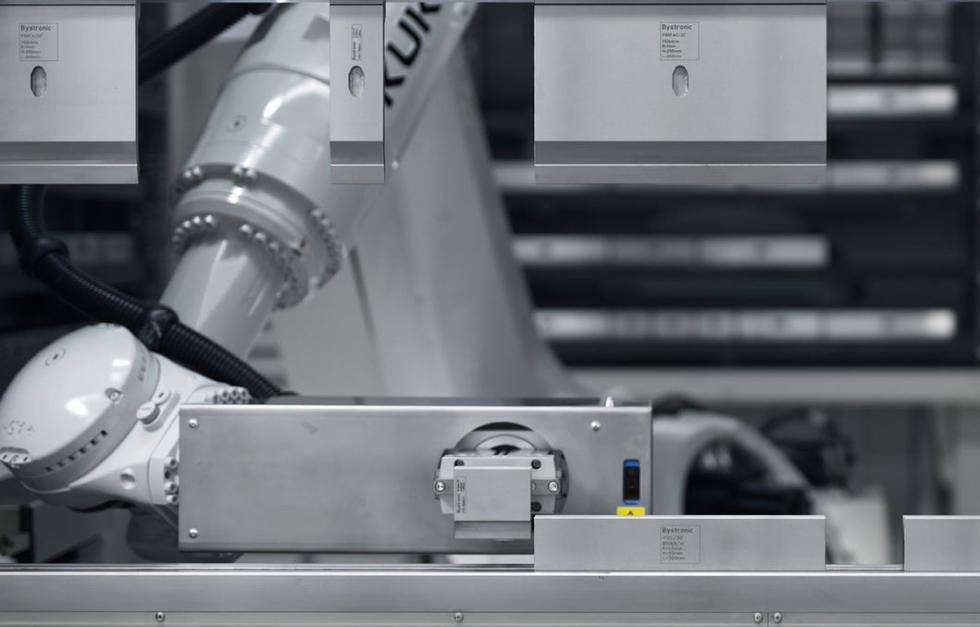

Make full use of the whole spaceFor large size cutting tool, also can realize automatic tool changing

The bearing capacity of the six axis manipulator is 25 kg.It can change the size V120 maximum under the knife, as well as the maximum height of 350 mm on the knife.When necessary, can also be knife on rotating 180 degrees.

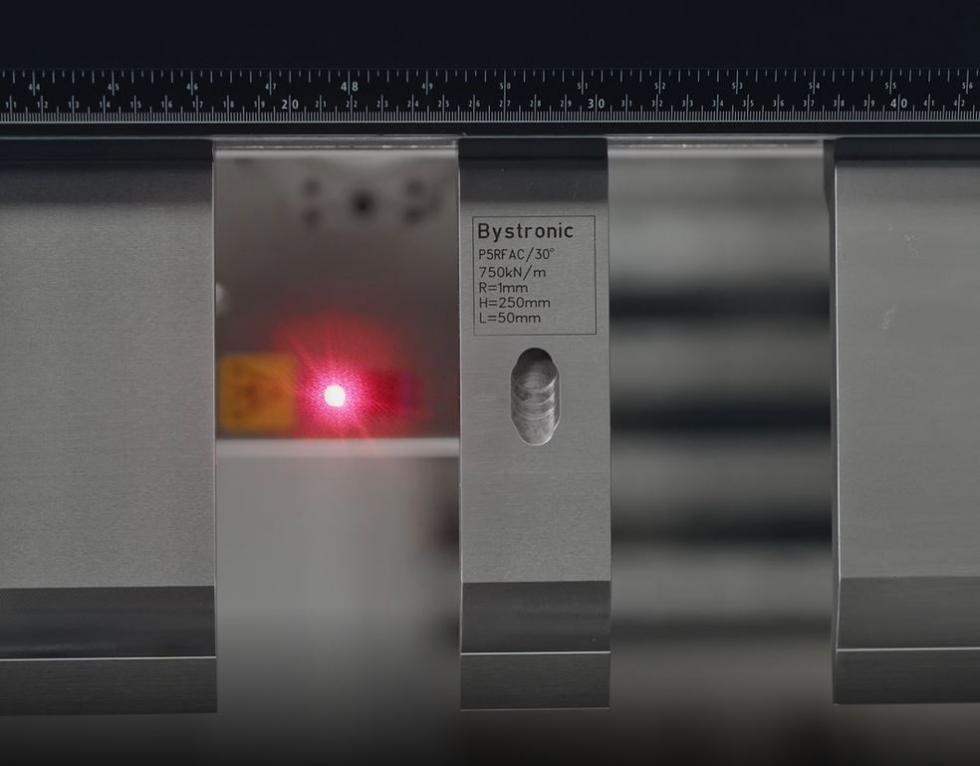

Intelligent software and sensor systemThrough the button operation integrating new tool

Modular Tool Changer and bending software BySoft Cell Control Bend forming linkage.Smart sensors automatically identify new tools and integrated into the tool library immediately.In this way, save the cost of programming.

Shorten the installation timeWith automatic tool change for bending processing speed

Don't waste your time: up to 70% of the time can take up load bending process.This is not only time-consuming, and cutting tools for large size is particularly exhausting.

Modular Tool Changer for your staff and burden and increase productivity.It can on your bending machine which Pro automatic changing tool, and ensure the high precision of bending process.

To protect your parts and toolsExtend the service life of cutting tools

Bending machine of automatic cleaning function to ensure the accurate positioning tool, and further improve the accuracy of bending process.Protective action to prolong tool life.

Make full use of the whole spaceFor large size cutting tool, also can realize automatic tool changing

The bearing capacity of the six axis manipulator is 25 kg.It can change the size V120 maximum under the knife, as well as the maximum height of 350 mm on the knife.When necessary, can also be knife on rotating 180 degrees.

Intelligent software and sensor systemThrough the button operation integrating new tool

Modular Tool Changer and bending software BySoft Cell Control Bend forming linkage.Smart sensors automatically identify new tools and integrated into the tool library immediately.In this way, save the cost of programming.

With our Modular Tool Changer, shorten the installation time and improve the quality of bending to the greatest extent.

Technical parametersAll the information about the Modular Tool Changer

| Modular Tool Changer | |

| Pressure tonnage | 100-320 t |

| Bending length, | 3100-4300 mm |

| Standard trip | 450 mm |

| Open the height | 840 mm |

| The depth of the throat and mouth | 400 mm |

| The width of the table | 74/110 mm |

| Tool storage capacity | 52 m |

| Knife on the biggest long | 515 mm |

| The maximum height | 350 mm |

| Die is biggest | 120 mm |

videoRapid and accurate: extremely flexible automation system

With automatic tool change, save time and improve the quality of bending.Tool suite will be accurately without wear positioning in the upper and lower work bedplate clamping system.Can automatically rotate on the knife, meet the demand of more diversified bending application.With the aid of modular design, can be mounted for which Pro series bending machine.

From the video window

To improve productivity

Automatic tool changer can easily add to all which Pro bending machine, and significantly shorten the installation time.

The precision of the highest

Bending the workbench of the automatic cleaning function to ensure precise positioning of a tool, and high precision of bending process.

To minimize wear and tear

Tool will be protected, and always cleanly in a knife in the library.It can reduce wear and prolong the service life of them.

No programming

Smart sensors automatically identify new tools and integrated into the tool library immediately.

If you folded bending machine automatic tool change have any questions, we are very happy to provide advice.

The super serviceCustomized according to your demand, to ensure smooth production

ByCare package

Our well-trained service professionals to ensure efficient production process and the safety of your employees.According to different requirements, we provide services ranging from basic package to comprehensive plans.

Comprehensive customer consultant

We will analyze your production and confirm what are the advantages and disadvantages.This, you can optimize processes and reduce downtime.

Our service

We offer you the super system maintenance and maintenance services.We can according to your request, to provide you with a modified upgrades or attachments, to adjust your machine.If necessary, we'll be able to overhaul.

Our service specialists at any time to provide you with fast and personalized service

softwareBySoft Cell Control Bend: used for bending machine software

Modular Tool Changer and bending software together.Tie-in tool changer sensing system, it can automatically identify the cutting tool and realize the integration.In this way, you can through the BySoft Cell Control Bend easily Control the whole process steps.