Which ProAchieve the highest performance of plate bending machine

High-tech bendingYou can fully trust our good quality

Whether simple or complex workpiece artifacts - relying on our plate bending machine, always ensure that the highest repeat precision.With the dynamic deflection compensation and patent type Pressure Reference technology, to ensure the stable quality.

The quality and performanceThe best performance and quality

With our flagship product, the bending speed ascend to a new level.Not just because of which Pro can carry on the processing at high speed.To meet strict processing requirements, which Pro plate bending function to hand over the same satisfactory answer.Intelligent auxiliary functions and patent type bending technology to ensure the stability of the high quality - starting from the first artifacts until the order is completed.

On time to meet customer demandFor the complex process of plate bending machine

Which Pro to ensure highest level of performance - even if the bending process of complex and ever-changing material also.With plate bending machine, you can also different thickness and quality of workpieces.In this way to complete your order - is faster, more flexible.

Use the best configurationThe correct plate bending machine allows you to win more time

The right machine production the right plate.From the performance of the complete configuration of ideal pressure tonnage.In 100, 150, 200, 250 or 320 tons, with the right plate bending machine, you can be as important to invest more time.

High-tech bendingYou can fully trust our good quality

Whether simple or complex workpiece artifacts - relying on our plate bending machine, always ensure that the highest repeat precision.With the dynamic deflection compensation and patent type Pressure Reference technology, to ensure the stable quality.

The quality and performanceThe best performance and quality

With our flagship product, the bending speed ascend to a new level.Not just because of which Pro can carry on the processing at high speed.To meet strict processing requirements, which Pro plate bending function to hand over the same satisfactory answer.Intelligent auxiliary functions and patent type bending technology to ensure the stability of the high quality - starting from the first artifacts until the order is completed.

On time to meet customer demandFor the complex process of plate bending machine

Which Pro to ensure highest level of performance - even if the bending process of complex and ever-changing material also.With plate bending machine, you can also different thickness and quality of workpieces.In this way to complete your order - is faster, more flexible.

Use the best configurationThe correct plate bending machine allows you to win more time

The right machine production the right plate.From the performance of the complete configuration of ideal pressure tonnage.In 100, 150, 200, 250 or 320 tons, with the right plate bending machine, you can be as important to invest more time.

With the right plate bending machine increase your production capacity.

Which Pro technology parametersAll information and data about which Pro.

| Which Pro 100, 150, 200, 250, 320 | |

| Pressure tonnage | 100-320 t |

| Bending length, | 3100-4300 mm |

| Open the height | 640, 840 mm |

| Standard trip | 250, 450 mm |

| BySoft Cell Control Bend |

|

Used for bending of plate bending machine tool

With the right tools, the hollow bending, stamping and three point bending to get perfect bending effect.With the original tool, you can give full play to the potential of plate bending machine.Bystronic bending tool clamping type (different) can be flexible to use, fully cover your various applications.If you need for your product design personalized special solutions, we are very happy to provide advice.

Our plate bending machine experts is very willing to provide support for you.

Bending features and options

-

Productivity and efficiency -

The quality of -

flexibility -

ease -

To meet the needs of the future -

Peace of mind safe -

Business success

Speed Options

Higher process speed - through Performance Edition and Dynamic choice between Edition, you will get higher working speed compared with the Classic Edition.

RFA clamping (Fast clamping System)

With a variety of hydraulic clamping system options, shorten the installation time.Through the automatic alignment tool, can realize ideal shortcut assignments.

Optical Bend behind the System

Will - with our Optical Bend behind the System, we will provide you with in the process of the bending and meticulous guidance services.

Fast Bend +

To ensure the best comfort and improve efficiency - with Fast Bend +, in your use of our bending machine can improve safety and reliability during the operation.

The Dynamic crowning

For which Pro, dynamic deflection compensation system can not only improve the speed, but also can realize fast cycle time.

LAMS

Excellent bending precision - optical Angle measuring system based on laser and camera of the machine are optimized by the sensor precision of bending.

Optical Bend behind the System

Will - with our Optical Bend behind the System, you will master all the information in the bending process.

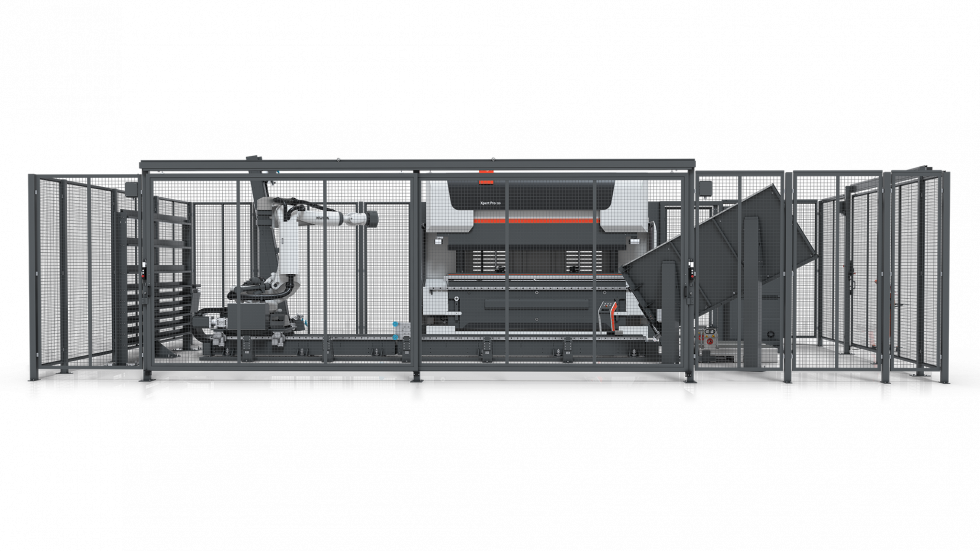

betway体育亚洲版Automation ready Modular Tool Changer

Dock, move, add, remove, or integrated workbench clean can be more efficient work - even in the case of unattended can be easily deal with.

Increased stroke and daylight

Increase stroke - on a narrow or a high profile and polygon workpieces, bending becomes more convenient.

Multi axes back the gauge

Improve flexibility - based on the complexity of the product, after the number of shaft block gauge will change between 1 and 6.

The Dynamic Sheet Supports

Easily guide in the process of bending thin plate - between bending auxiliary devices and bending process to realize synchronous control.

Detachable Bending line laser

Apply to all after block gauge system shall not apply to the application

ByVision Bending

Interface simple and intuitive.

Optical Bend behind the System

With our Optical Bend behind the System, you will master all the information in the bending process.

Fast Bend +

In your use of our bending machine to carry out the operation process, Fast Bend + enhance safety for you.

Multi axes back the gauge

After simplify the complexity of the production, according to the product, the number of shaft block gauge will change between 1 and 6.

Energy Saver HYBRID & SERVO (Energy & Noise reduction)

We drive system is equipped with a special control system.In this way, can be achieved: the power, to each according to his need higher working speed, reduce electricity consumption and reduce noise

betway体育亚洲版Automation ready

We can extend in all types of machines for automation solutions.

Optical tool detection

Shorten the installation time and improve reliability

betway体育亚洲版Automation ready Modular Tool Changer

With different functions, such as dock, move, add, remove, or integrated workbench clean to achieve more efficient work, even in the case of unattended can be easily deal with.

The Dynamic crowning

The dynamic deflection compensation is used for bending machine which Pro system allows you to improve the working speed and speed up the cycle time of benefit.

LAMS

The optical Angle measuring system based on laser and camera by sensors improve machine precision of bending.

betway体育亚洲版Automation ready

We can extend in all types of machines for automation solutions.

Energy Saver HYBRID & SERVO (Energy & Noise reduction)

We drive system is equipped with a special control system.In this way, can be achieved: the power, to each according to his need higher working speed, reduce electricity consumption and reduce noise

Speed options

Higher process speed - through Performance Edition and Dynamic choice between Edition, you will get higher working speed compared with the Classic Edition.

Increased stroke and daylight

Increase stroke - on a narrow or a high profile and polygon workpieces, bending becomes more convenient.

betway体育亚洲版Automation ready

Our machines are extended to automation solutions.

Optical Bend behind the System

All information is in our hands - with our Optical Bend behind the System, you will master all the information in the bending process.

Speed Options

Higher process speed - through Performance Edition and Dynamic choice between Edition, you will get higher working speed compared with the Classic Edition.

RFA clamping (Fast clamping System)

With a variety of hydraulic clamping system options, shorten the installation time.Through the automatic alignment tool, can realize ideal shortcut assignments.

Optical Bend behind the System

Will - with our Optical Bend behind the System, we will provide you with in the process of the bending and meticulous guidance services.

Fast Bend +

To ensure the best comfort and improve efficiency - with Fast Bend +, in your use of our bending machine can improve safety and reliability during the operation.

The Dynamic crowning

For which Pro, dynamic deflection compensation system can not only improve the speed, but also can realize fast cycle time.

LAMS

Excellent bending precision - optical Angle measuring system based on laser and camera of the machine are optimized by the sensor precision of bending.

Optical Bend behind the System

Will - with our Optical Bend behind the System, you will master all the information in the bending process.

betway体育亚洲版Automation ready Modular Tool Changer

Dock, move, add, remove, or integrated workbench clean can be more efficient work - even in the case of unattended can be easily deal with.

Increased stroke and daylight

Increase stroke - on a narrow or a high profile and polygon workpieces, bending becomes more convenient.

Multi axes back the gauge

Improve flexibility - based on the complexity of the product, after the number of shaft block gauge will change between 1 and 6.

The Dynamic Sheet Supports

Easily guide in the process of bending thin plate - between bending auxiliary devices and bending process to realize synchronous control.

Detachable Bending line laser

Apply to all after block gauge system shall not apply to the application

ByVision Bending

Interface simple and intuitive.

Optical Bend behind the System

With our Optical Bend behind the System, you will master all the information in the bending process.

Fast Bend +

In your use of our bending machine to carry out the operation process, Fast Bend + enhance safety for you.

Multi axes back the gauge

After simplify the complexity of the production, according to the product, the number of shaft block gauge will change between 1 and 6.

Energy Saver HYBRID & SERVO (Energy & Noise reduction)

We drive system is equipped with a special control system.In this way, can be achieved: the power, to each according to his need higher working speed, reduce electricity consumption and reduce noise

betway体育亚洲版Automation ready

We can extend in all types of machines for automation solutions.

Optical tool detection

Shorten the installation time and improve reliability

betway体育亚洲版Automation ready Modular Tool Changer

With different functions, such as dock, move, add, remove, or integrated workbench clean to achieve more efficient work, even in the case of unattended can be easily deal with.

The Dynamic crowning

The dynamic deflection compensation is used for bending machine which Pro system allows you to improve the working speed and speed up the cycle time of benefit.

LAMS

The optical Angle measuring system based on laser and camera by sensors improve machine precision of bending.

betway体育亚洲版Automation ready

We can extend in all types of machines for automation solutions.

Energy Saver HYBRID & SERVO (Energy & Noise reduction)

We drive system is equipped with a special control system.In this way, can be achieved: the power, to each according to his need higher working speed, reduce electricity consumption and reduce noise

Speed options

Higher process speed - through Performance Edition and Dynamic choice between Edition, you will get higher working speed compared with the Classic Edition.

Increased stroke and daylight

Increase stroke - on a narrow or a high profile and polygon workpieces, bending becomes more convenient.

betway体育亚洲版Automation ready

Our machines are extended to automation solutions.

Optical Bend behind the System

All information is in our hands - with our Optical Bend behind the System, you will master all the information in the bending process.

videoThe function of the intelligent use which Pro plate bending machine to ensure the excellent quality

Precision began the first artifacts, which Pro operator to save a lot of work and can do for you.Therefore, provides the intelligent auxiliary functions, including LAMS Angle measuring system and material curve generator.

Video highlights

The highest performance

We carry the flagship product of high bending technology can meet the most stringent requirements.Even complex orders, our plate bending machine can also ensure that the process of the highest speed.

Flexible configuration

The performance of the complete configuration, can be customized to application field matching pressure tonnage - from 100 to 320 tons.

The precision of the highest

Intelligent auxiliary functions, including material LAMS curve generator and the Angle measuring system to ensure the best accuracy.

The stability of the bending quality

Innovation of mechanical structure to realize bending when the highest repeat precision.Our plate bending machine with the dynamic deflection compensation and patent type Pressure Reference technology convincing.

Video tutorial

Born to automationSolution is suitable for the plate bending machine

Use our automation solution of plate bending machine to improve the quality of your bent.To do this, you don't need any programming costs.For example, through the automatic bending tool replacement, you can also save time.With the right automation solution, can efficient and correct handling of various orders.

The super serviceCustomized according to your demand, to ensure smooth production

ByCare package

Our well-trained service professionals to ensure efficient production process and the safety of your employees.According to different requirements, we provide services ranging from basic package to comprehensive plans.

Comprehensive customer consultant

We will analyze your production and confirm what are the advantages and disadvantages.This, you can optimize processes and reduce downtime.

Our service

We offer you the super system maintenance and maintenance services.We can according to your request, to provide you with a modified upgrades or attachments, to adjust your machine.If necessary, we'll be able to overhaul.

Our service specialists at any time to provide you with fast and personalized service

softwareOperation is simple: let the software

On a touch screen display all process steps: with BySoft Cell Control Bend, you can intuitive and easy to Control your plate bending machine.Intelligent software to create the ideal bending process, and recommend the right tool for you.